Warmfloor Insulated Flooring

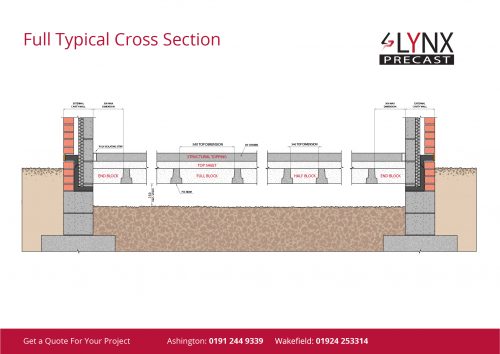

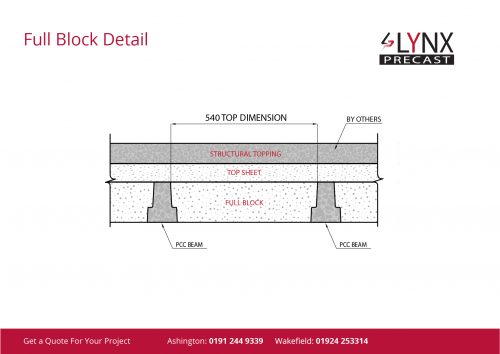

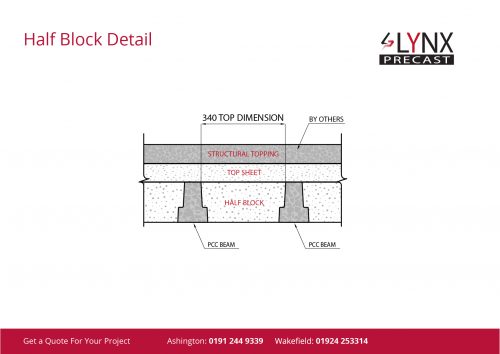

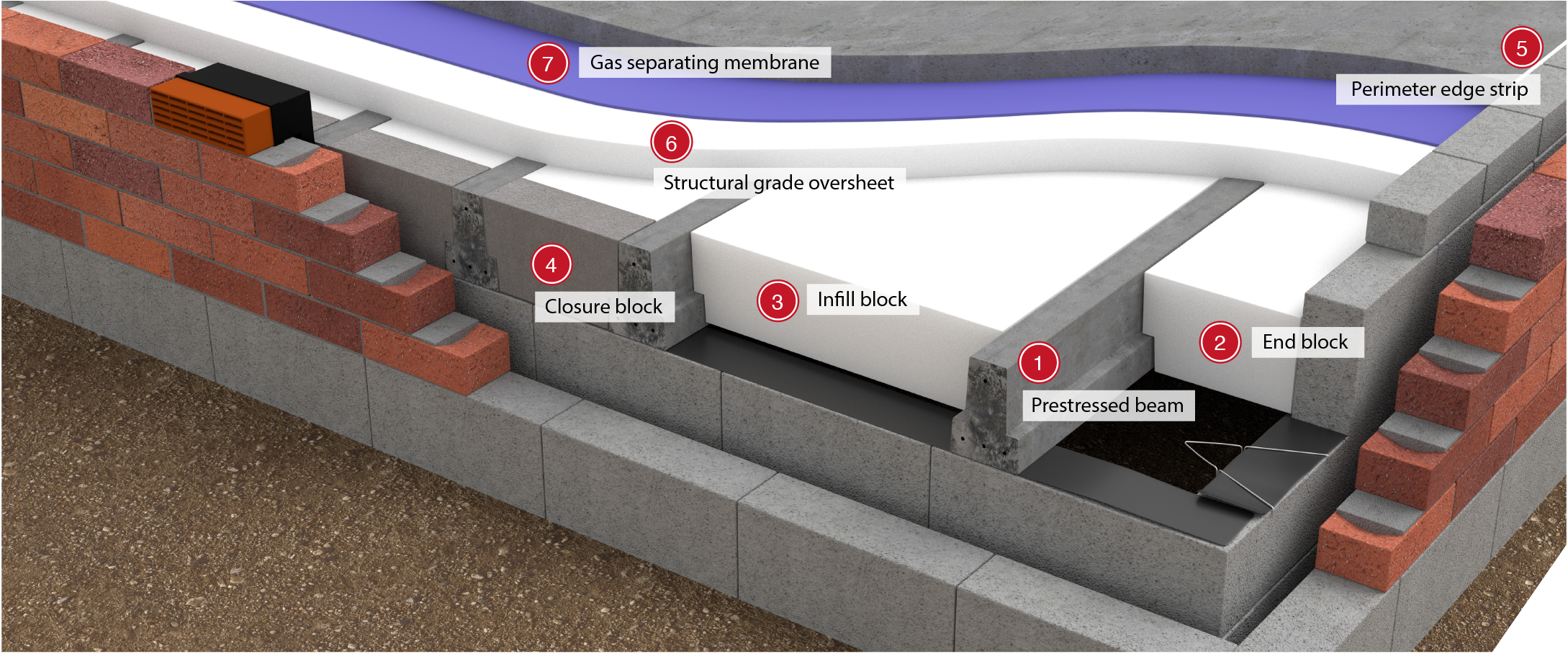

Insulated Warmfloor, utilises 150mm or 225mm deep prestressed concrete beams in conjunction with highly insulating high strength expanded polystyrene blocks and components. A nominal 75mm structural concrete topping completes the flooring system. The resulting floor is a thermally efficient and cost effective solution. U values below 0.10w/m²K can be achieved by increasing the thickness of the EPS in the floor construction.

EPS is an environmentally friendly sustainable product with an ODP of zero, A+ BRE Green Guide rating and 100% and is recyclable with the efficient use of natural resources, for every 1 kilogram of oil used in the manufacture of EPS, 150 kilograms can be saved in heating oil over a fifty year period.

Insulated Flooring

Systems

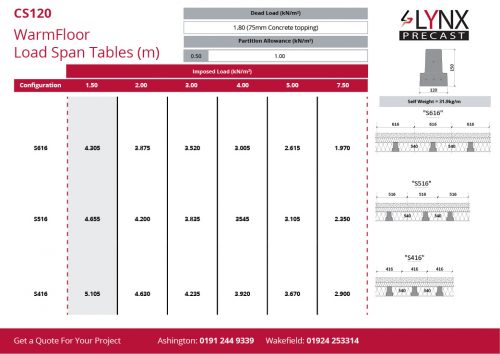

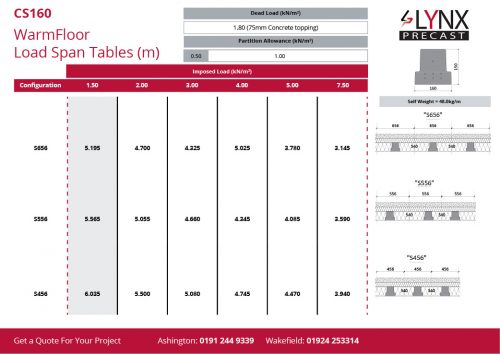

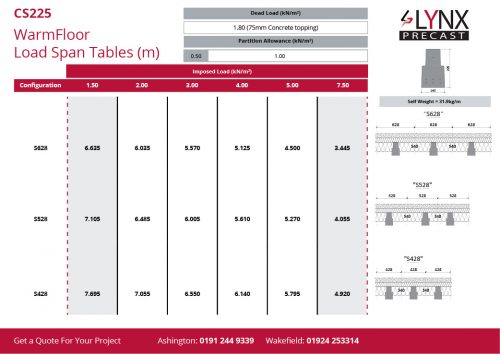

Prestressed Concrete T beams manufactured in 150mm or 225mm depths in 50mm increments with high strength expanded polystyrene insulation blocks.

Insulated Flooring products are manufactured from environmentally friendly expanded polystyrene. EPS is a very sustainable product and an efficient use of natural resources, for every 1 kilogram of oil used in the manufacture of EPS, 150 kilograms can be saved in heating oil over a fifty year period.

Call For a Quote from

Ashington:

0191 244 9339

Call For a Quote from

Wakefield:

01924 253314

Lynx Warmfloor Installation Guide

Applications

Ground floors in domestic and residential buildings

Benefits

- Highly insulated floor

- Flexible ‘U’ values as low as 0.10w/m2K (depending on Perimeter/Area ratio)

- Easy and quick to install EPS blocks, mechanical lifting equipment not required

- No skilled trades required to install

- No waste

- Underfloor heating can be incorporated into the concrete finish

- Non toxic, non irritant and chemically inert.

- A+ BRE Green Guide rating.

- Zero ODP

- Certified by BBA (Agrément Certificate 17/5431 – S and B Warmbeam)

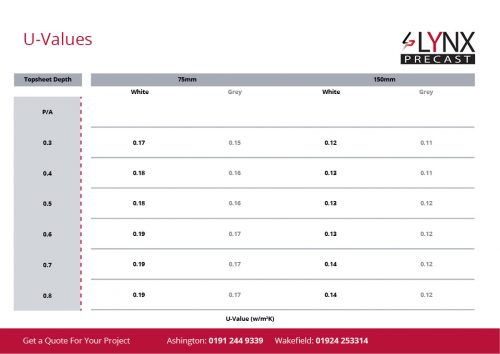

U-Values

U-values

Warmfloor will help to enhance the thermal performance and efficiency of a building and can achieve ‘U’ values as low as 0.10 The “U” value is a measure of how easy it is for heat to pass through the fabric of a building measured in W/m²K, that is heat (watts) passing through each square metre (m²) for each 1⁰C of temperature difference. Warmfloor can be specified with a range of “U” values that will ensure the building meets its thermal efficiency target. The table gives the U values based on Perimeter/Area (P/A) using either standard white EPS or grey EPS. Grey EPS has added graphite which improves its insulating properties. The thermal performance of the floor can be improved by simply increasing the thickness of the topsheet.

Thermal Bridging

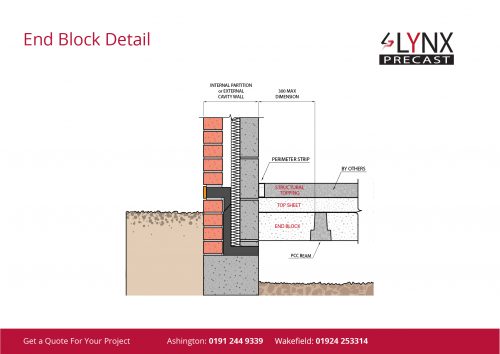

A thermal bridge is an area of building construction which has a significantly higher heat transfer than the surrounding materials, this can occur at the junction between the floor and the wall reducing the thermal efficiency of the building. The measure of this heat loss at the thermal bridge is known as the PSI (Ψ) value measured in W/mK The use of Lynx warmfloor can result in reduced PSI values much less than Accredited Construction Details of 0.16 W/mK increasing the thermal efficiency of the building.

Concrete Toppings

Concrete

| Standard Concrete: 65mm min depth (above services) |

C28/35 with maximum aggregate size 20mm and reinforcement selected from the options below. Slump should be Class S3 (100 to 150mm) or S4 (for spot samples taken from initial discharge, 140 to 230mm). Aggregate to comply with BS EN12620: 2013. |

| Self Compacting Concrete: 65mm min depth (above services) |

C28/35 with maximum aggregate size 10mm and reinforcement selected from the options below. Slump flow class should be SF1 (550 to 650mm) or SF2 (660 to 750mm). The sand content should be greater than 45%. Aggregate to comply with BS EN1260:2013. |

Reinforcement

| Steel Mesh | One layer of A142 mesh (to BS 4483:2005) with a characteristic yield strength of 500N/mm² set at mid-point to the depth of the concrete topping. |

| Steel Fibres | Novomesh B&BA: Dosage rate 17.5kg/m³, steel flat end, steel fibres, 50mm long, 1mm diameter, tensile strength of 1150N/mm². |

| Steel Fibres | Adfil SF86: Dosage rate 7.5kg/m³, 60mm long, 0.75mm diameter, modulus of elasticity of 200000N/mm², tensile strength of 1225N/mm². |

| Steel Fibres | Zenith 60: Dosage rate 10kg/m³, 60mm long, 1mm diameter, modulus of elasticity of 200000N/mm², tensile strength 1500N/mm². |

| Steel Fibres | Sikafiber-1050 B&BA HF: Dosage rate 11.5kg/m³, 50mm long, 0.75mm diameter, tensile strength 700N/mm². |

| Steel Fibres | ABC: Dosage rate 12.5kg/m³, 60mm long, 0.75mm diameter, modulus of elasticity of 210000N/mm², tensile strength 1200N/mm² |

| Steel Fibres | Apex 60: Dosage rate 7.5kg/m³, 60mm long, 1mm diameter |

| Macro-Polymer | Novomesh B&BA: Dosage rate 3.84kg/m³, continuously deformed, 60mm long, 0.56mm diameter, modulus of elasticity of 7000N/mm², tensile strength 600N/mm². |

| Macro-Polymer | Durus Easy Finish: Dosage rate 2.5kg/m³, 40mm long, 0.7mm diameter (equivalent), modulus of elasticity of 6000N/mm², tensile strength of 470N/mm². |

| Macro-Polymer | Nexus 85: Dosage rate 2.5kg/m³, 60mm long, 0.7mm diameter, modulus of elasticity of 5000N/mm², tensile strength 375N/mm². |

| Macro-Polymer | ABC: Dosage rate 5.0kg/m³, 55mm long, 0.65mm diameter, tensile strength 510N/mm² |

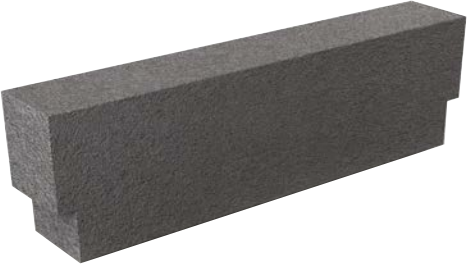

Prestressed Beam

150mm or 225mm

Lightweight Concrete Closure Block

540mm

Lightweight Concrete Closure Block

340mm

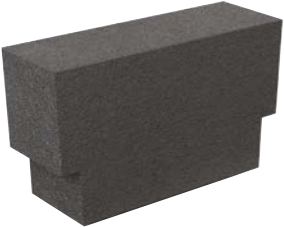

EPS Starter / End Block

300mm / 178mm

EPS Infill Block

340mm

EPS Infill Block

540mm

EPS Structural Grade Oversheet

2400mm x 1200mm

EPS Perimeter Edge Strips

30mm x 75mm x 1200mm