Products

We manufacture and supply a range of T beams, hollowcore slab,

stairs and lift shafts to suit residential, commercial and industrial

buildings across the uk.

All of our precast concrete products are manufactured in

factory controlled conditions using the latest machines,

technology and software.

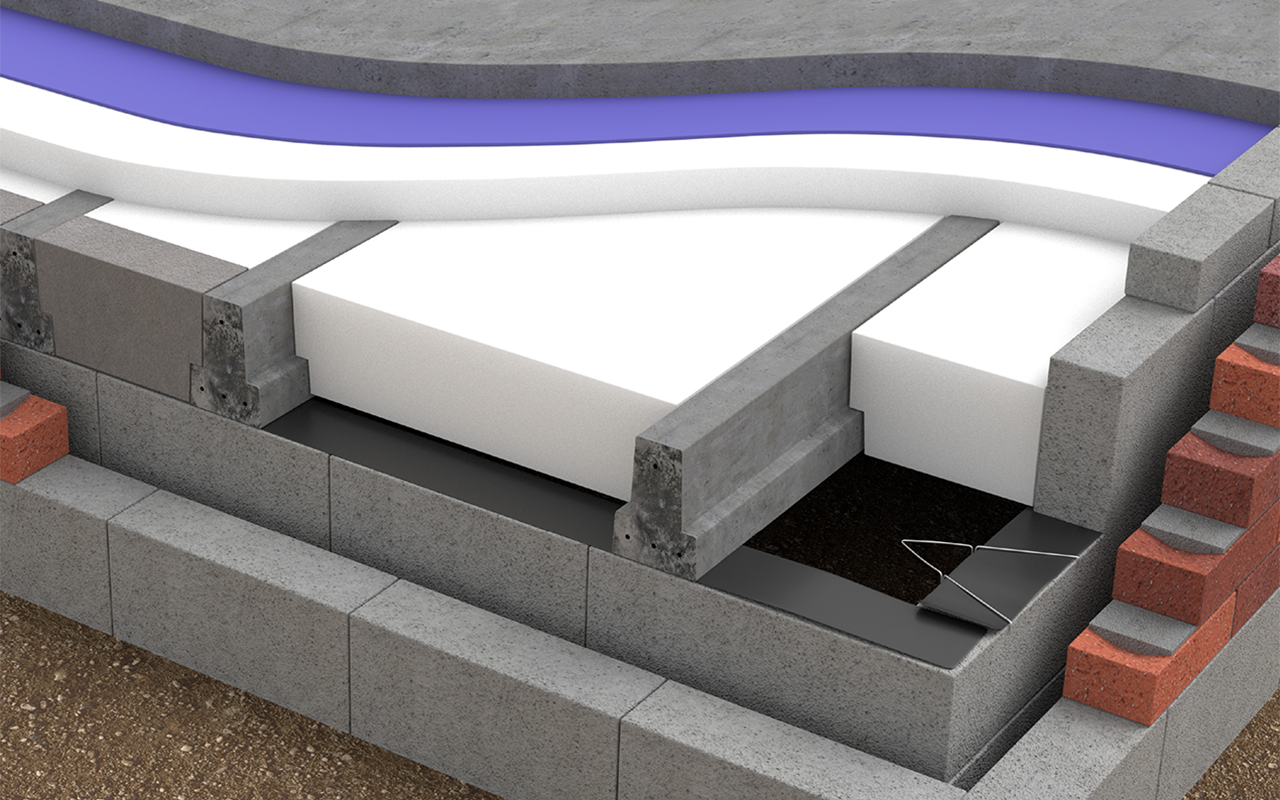

Beam and Block

Cost effective, time efficient, high quality ground floor solution (In photo)

At Lynx Precast we have many years experience in the design, manufacture and installation of precast concrete beam and block flooring systems.

Our prestressed beams are made in a factory controlled environment resulting in a high quality finish and dimensional accuracy. All beams are clearly marked with a batch number, length and weight and manufactured in accordance with relevant British and European Standards.

Warmfloor Insulated Flooring

Warmfloor utilises 150mm or 225mm deep prestressed concrete beams in conjunction with highly insulating high strength expanded polystyrene blocks and components. A nominal 75mm structural concrete topping completes the flooring system. The resulting floor is a thermally efficient and cost effective solution. U values below 0.10w/m²K can be achieved by increasing the thickness of the EPS in the floor construction.

EPS is an environmentally friendly sustainable product with an ODP of zero, A+ BRE Green Guide rating and 100% recyclable.

Hollowcore Flooring

Our Hollowcore concrete floor units offer high span capacity with light weight and can be supplied with factory formed holes, notches and open cores to satisfy various structural design requirements.

‘Acoustic’ slabs are manufactured to satisfy the requirements of Part E of the building regulations, Resistance to Sound.

Hollowcore concrete flooring is available in depths from 100 – 250mm

Lift Shafts

Lynx design, manufacture, and install precast concrete lift shafts, including lift pit and capping lids.

These are produced in high tolerance adjustable steel moulds in a factory-controlled environment. Door openings and cast in inserts and channels can be accommodated in the manufacturing process.

Precast concrete lift shafts are becoming much more popular, with high demand for offsite construction. Speed of build and no requirement for scaffold are key benefits over other methods of construction.

Manufactured in single, double, or triple cell configuration with a maximum inner core size of 7800 x 3400. Wall thickness from 125mm to 225mm.

The Benefits

of precast

Building in precast allows faster speed of construction, reduced cost per unit & minimisation of waste.

- All Lynx products are manufactured in a factory-controlled environment. On site construction needs additional time, labour and materials such as mixing, placing, formwork and curing time. This method also produces a great amount of waste materials which precast eliminates.

- Precast offers excellent acoustic performance, reducing sound making it the perfect choice for upper floors in homes, apartments, care homes and hospitals.

- Speed of Build. Off site construction allows efficient build times, not being subjected to hold ups associated with site, such as adverse weather conditions.

Precast also offers an earlier working platform, giving instant access to follow on trades.

Precast Liftshafts are quick and easy to install and reduce the need for temporary works. Our precast stairs allow immediate safe access to upper floors.

- Fire Resistant. Precast Concrete is non combustible and fire resistant, the risk and effects of fire are significantly reduced in terms of health and safety, the financial impact and extent of remedial works.

- Durability. Precast concrete has a lifespan of over 100 years. As well as being fire resistant, weather resistant and watertight, it can also resist many corrosive materials.

- Our precast flooring is suited to longer spans opening internal spaces allowing for greater design flexibility.

- The use of precast concrete can help reduce the whole life carbon footprint of a building.

Health & Safety

Lynx Precast are committed to ensure that its operations do not adversely affect

the health, safety and welfare of its employees, contractors, visitors or members

of public by:

- Allocating sufficient resources and support to implement the policy.

- Identifying, planning for, and controlling the risks associated with our activities.

- Providing adequate supervision, education and training resulting in highly motivated and competent employees.

- Monitoring the implementation and effectiveness of the policy at regular intervals.

- We aspire to set the highest health and safety standards to promote the confidence and trust of our employees, suppliers and customers.

Quality

Lynx Precast has built a reputation for producing consistent, high quality products off site in factory-controlled conditions. Our products and processes comply with all relevant standards and our quality management system is accredited to BS EN ISO 9001.

All products are clearly printed with project details, unit information, manufacturing date, dimensions and weight ensuring full traceability and quick reference in the event of any query.

Factory Production control accreditation requires us to rigorously check dimensions and physical properties of our products. Once installed, you can be confident that they will be fit for purpose and meet the specification.

Sustainability and the Environment

We are committed to sustainable development as a guiding principle within our work. Concern for the environment is a fundamental prerequisite and we aim to reduce the impact of our operations on the environment by:

- Promoting responsibility for the environment throughout the organisation at all levels.

- Complying with all relevant legislation and regulations. Our environmental management system is accredited to ISO 14001.

- Reducing the use of energy, water and other resources.

- Minimising waste and increase the use of recycling.

- Using cement replacements and reducing embedded carbon in our products.

- Continual investment in the most up to date and technologically equipment available.

- Organising product deliveries and promoting the most economic use of delivery vehicles.

- Providing adequate resources and capital investment to enable commitment to this policy.

Some examples of our ongoing progress are detailed below.

After investment exceeding £600K in the last 12 months more than 50% of our forktruck fleet are fully electric zero emission.

No waste products leave site until they are fully recycled into crushed concrete and steel. A proportion of the crushed concrete aggregates are reused in fresh concrete mixes.

All uncured concrete is fully processed by a concrete recycling plant, the reclaimed aggregates and water are reused in fresh concrete mixes. Over 20% of our water usage is reclaimed.

Every light on site including offices and yard has been converted to energy efficient LED units.

Company policies

Company policies and procedures provide a road map for our day to day operations. They ensure compliance with laws and regulations and are important in the reduction of risks and disruption. These policies provide assurance to staff, customers and the general public.

-

Responsible Sourcing and Sustainability Policy

Health & Safety Policy Statement

Mental Health & Wellbeing Policy